For those of you riveted to your seats awaiting continued coverage our printing equipment prepare yourselves. Second, but by no means second best comes our old style Chandler and Price 8x12.

The serial number of this press places it somewhere around late 1896 as the date of manufacture. We obtained the press through sheer chance. We happened to find a gentleman in St Louis selling the press condition unknown but willing to deliver to Houston. After exchanging some pictures and emails the press arrived, intact, and in far better shape then expected Thanksgiving weekend of last year. Mechanically all seemed well with little play in the linkages , little rust, and freely spinning operation. The catch, and there always is one, is that the press was coated solid with a quarter inch of what appeared to be waxy, congealed grease (photos below courtesy of seller, prior to delivery).

We cleaned. We scrubbed. The waxy grease came off. So did the paint. And cast iron oxidizes fast when exposed to the atmosphere. Real fast.

History is paved with otherwise level headed individuals who achieve acts of greatness through moments of blinding obliviousness and sheer idiocy. Sure, why can't we sail around the world? A flying jump kick through a flaming hoop- no problem! Our moment would be where I uttered the phrase "We're going to have to disassemble and repaint the press". Idiocy indeed. The wrenches and wire wheels came out, fingers were smooshed and blackened, and I spent a month looking like a coal miner in some kind of new age Dickens play. The work was akin to a vacation stay in the seventh ring of hell. Wire wheel all the gunk off a part. Take a break. Return to find that you hadn't wire wheeled all the gunk off the part. Repeat.

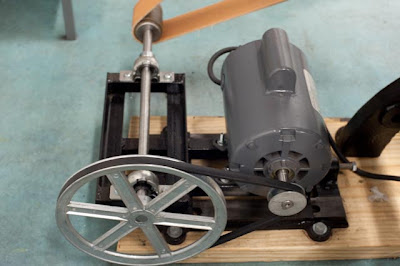

Eventually success was achieved. Black and red paint were applied as befitting any badass machine. I cut and finished new feed and delivery tables. But we had no power. The original motor was toast so we needed a new motor and a way to mount it. After some deliberation we decided to purchase a cheap and readily available 1725 rpm 1/2 HP 110 AC motor and reduce the speed through a belt drive system so that it was appropriately safe for hand feeding. The final speed is about twenty impressions per minute which gives plenty of time to put paper in and get hands out safely. We fabricated the motor mount using bearings and angle iron sourced from Mc Master Carr industrial.

Another issue with the press was the rails that the ink rollers ride on. Older presses tend to generate waves and dips in their rails through normal wear and tear which can lead to uneven plate inking. This was the case for our press. Luckily old style Chandler and Prices have roller rails that are under type high. In short, we had room to face the rails with material and still ink our plate correctly. I chose to fabricate some adjustable rails using aluminum angle bracket. It repaired the waves in the rails and allowed us to make minute adjustments to roller height if needed. You can see the results in the below photo- the strips with the three visible screws are the roller rails.

The end result of all the toil is a press that runs almost silently and vibration free and looks stunning to boot. A special thanks to our good friends Chris and Zach for some welding and CNC machining of some crucial replacement parts.

And now- a video!

3 comments:

dudes. deserving of the title "Badass Machine" indeed. can't wait to drool on that new paint in person!

Bee-yoo-ti-ful. Well done and it looks like a joy to use. Enjoy it - I have no doubt you will!

'tis a thing of beauty indeed

Post a Comment